|

| SERVICES |

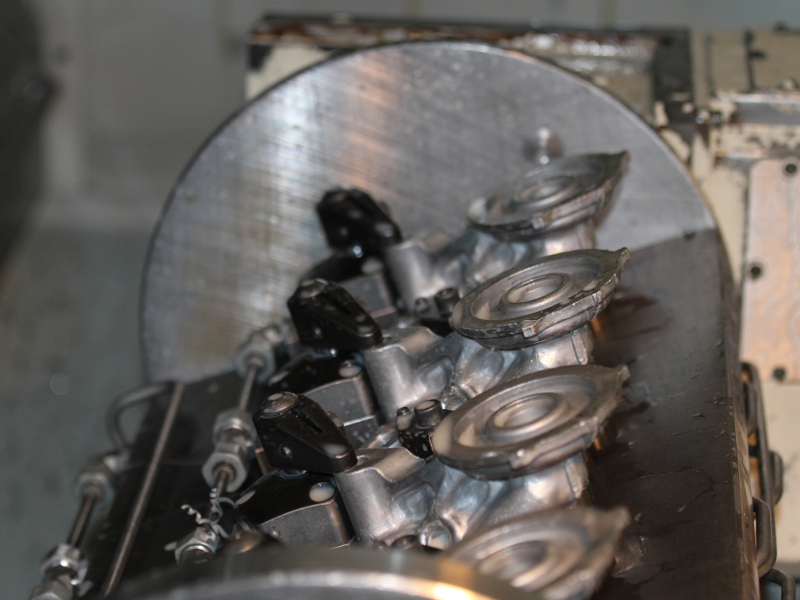

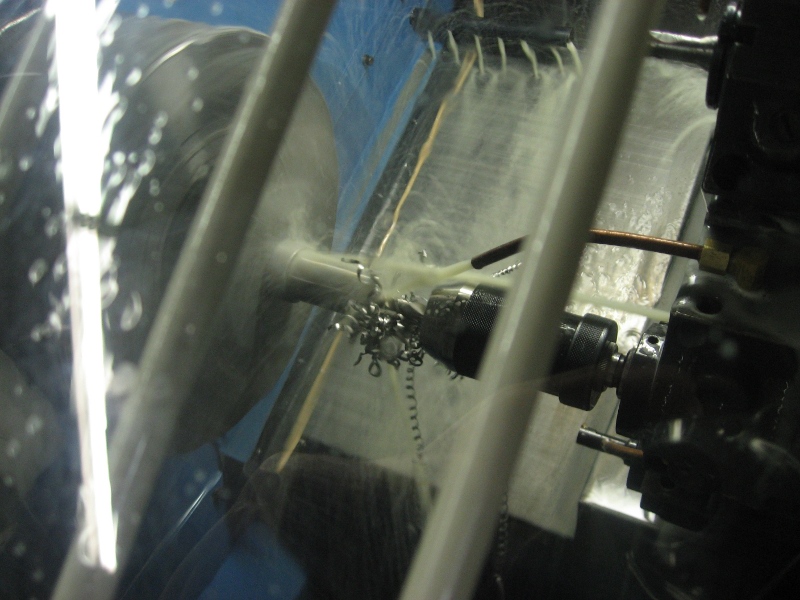

CNC Automotive Production Machining |

|||

|

|

|

|

Nixon Integrated offers 25 years of full service CNC production machining at competitive costs. From machining castings, forgings, billet, and bar stock material we can offer a full solution from quotation to production. Our simple goal is to provide the North American foundries with a cost competitive machining and assembly solution while ensuring on-time delivery and quality excellence. |

|||

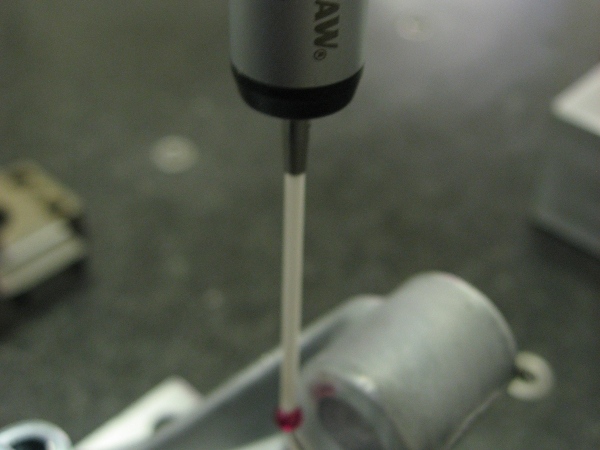

CNC Small Volume Machining |

|||

|

|

|

|

From small volume or lot production to prototype work we have nine CNC machine tools to produce your part. |

|||

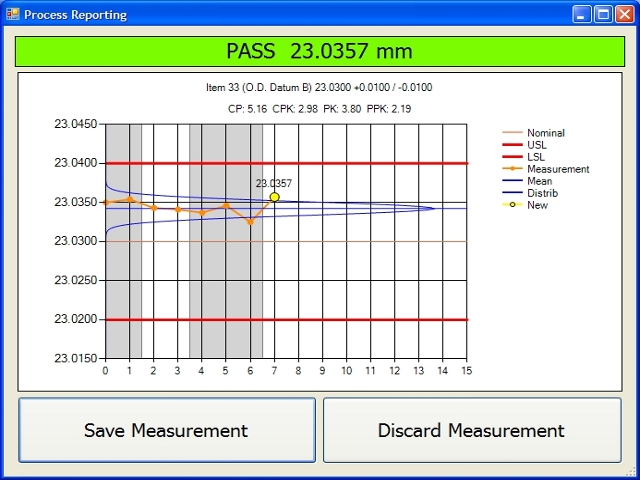

Quality System |

|||

|

|

|

|

Nixon Integrated is an ISO 9001:2015 certified facility with full PPAP and CMM capabilities. Our experienced quality engineers will ensure that your automotive standard PPAP packages are complete with full poke-yoke and pass through characteristics identified and controlled. Our Xcel CMM offers a 900mm x 1500mm x 900mm measurement volume to provide full dimensional layouts. Combined with our standard SPC software, including full CNC feedback, your key characteristic measurement challenges will be overcome. |

|||

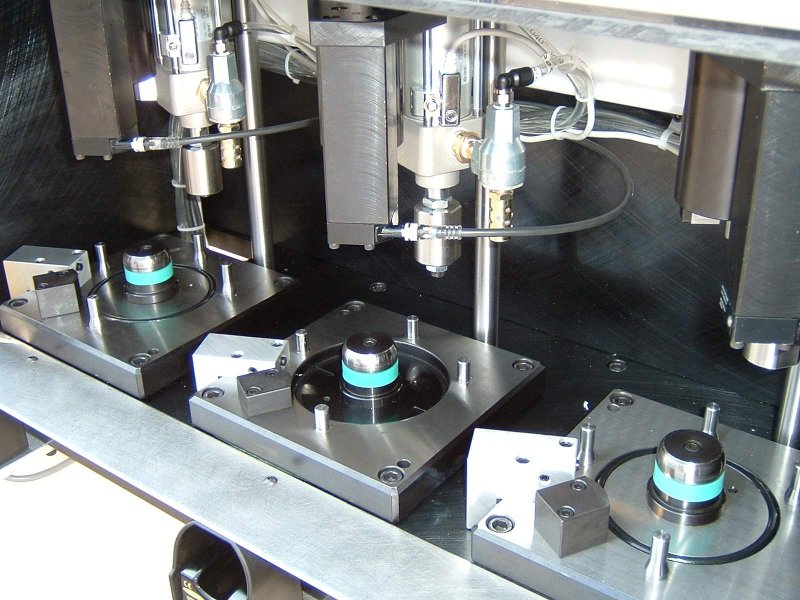

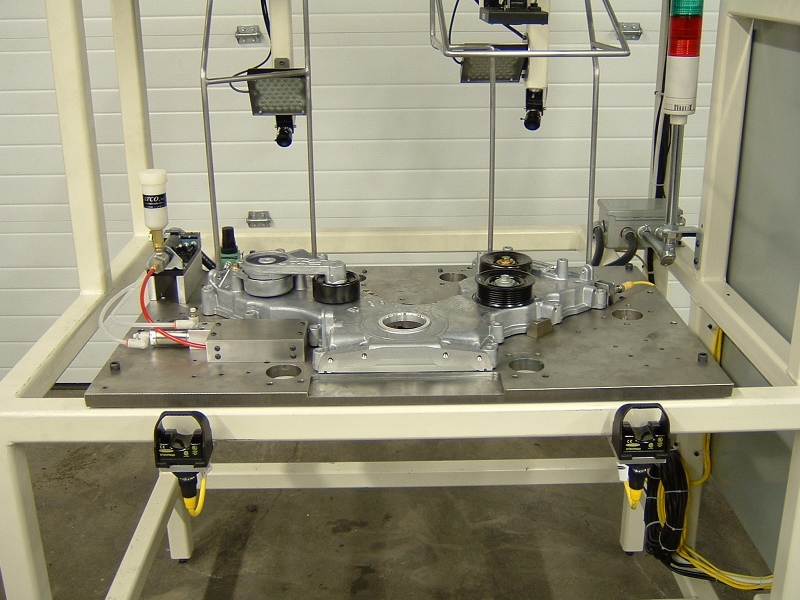

Accessory Equipment |

|||

|

|

|

|

Nixon Integrated designs and builds all the accessory equipment needed to support full production of your automotive parts. Standard casting pressure test / leak testing is done with "best practice" designs offering repeatability and accuracy. Semi and fully automated dowel presses offer dowel position, height, and insertion force inspection. Several machines for the assembly of gaskets, dowels, tubes, sensors, and glue applications have all been designed and built here.

|

|||

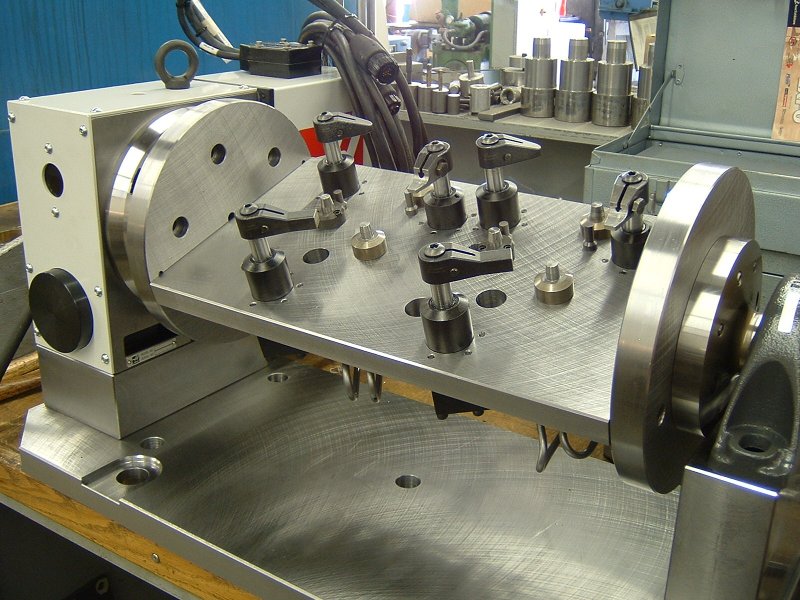

Toolroom Services |

|||

|

|

|

|

Our toolroom can support your production facility or your next machine build. Simply send us a drawing! |

|||

| CONTACT |

|

James Nixon (President) james.nixon@nixonintegrated.ca Telephone: (905) 336-2527 Address: Nixon Integrated Machining Designs Ltd. 3291 Mainway Units 5 & 6 Burlington, Ontario L7M 1A6 |

|

|